Saba Dilijan Bitumen Refining Company, according to the requirements of quality and safety control systems, has operating license number 4270 and all the valid certificates of the National Iranian Oil Company and the National Standard Organization of Iran, and has production units, offices, facilities, storage tanks, Laboratory, control room, unloading and loading, open and covered warehouses and all industrial necessities are according to the world standards. Saba bitumen company, by using internal resources and expert forces, can account for about 5% of the export bitumen production of the whole country, and also with an area of more than 20,000 square meters, being located in the center and transit highway of the central provinces, as one of the most important Bitumen supply centers in the country are equal to international

standards.

This company has two separate bitumen production units with full refinery reactors and

equipped with advanced distillation column system, and in its development plans, it will build AC-30 viscosity bitumen units and MC250, MC30, MC70 soluble bitumen units, as well as light and heavy hydrocarbon production units. It follows seriously. Currently, the product of Saba bitumen company is 70/60, 100/85 bitumen, road construction solution bitumen, viscosity bitumen, and MC bitumen types, the unit feed of which is only vacuum batom (VB) produced in the domestic refineries of the country and petroleum base solvents of the refineries. Iran is without any additives.

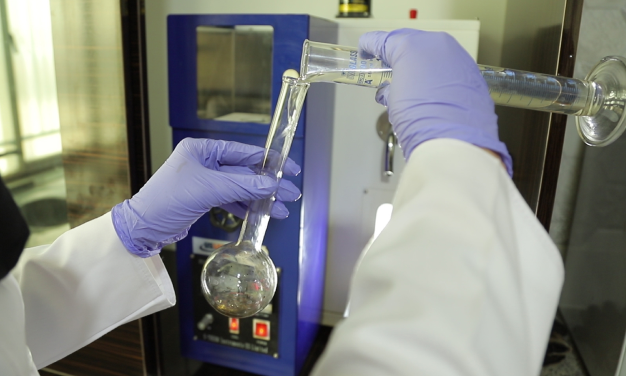

Bitumen saba company’s laboratory has controlled the production process in three stages by performing the necessary tests so that the bitumen production unit can produce the best products with standard conditions by making the necessary changes. All tests required in the quality control stages before production, during production and after production using the latest technology and advanced devices according to international standards are carried out in the laboratory of this company on all types of bitumen by experienced specialists and experts.

The daily production capacity of all types of soft bitumen in each of units 1 and 2 according to the design is 2700 barrels per day and the total production of factory products is 1000 tons per day

At present, Saba bitumen company, having two 2500-barrel bitumen tanks, with a capacity of more than 2000 tons of materials, keeps its various bitumen products for supply to customers. Also, 6 tanks with different capacities have been used to store 2500 barrels of bitumen and 200 tons of other materials

The barrel making unit of Qir Saba Company with an average daily production capacity of 1000 barrels, which is equivalent to more than 200 tons per day, is being implemented and operating in a separate facility of 1000 square meters

In the Bitumen saba Refinery Unit, by using two unloading arms and two loading platforms, a total of four tankers simultaneously unload and load in a complex of 5000 square meters with a total daily capacity of more than 1000 tons of all kinds of bulk materials. Also, this company has the ability to make all kinds of bitumen containers. A 60-ton scale also weighs the incoming and outgoing products.

The fire fighting system is used to extinguish the fire, keep the tanks and pipes for transferring materials and production operations warm, supply the air required by the production unit, control and feed the electricity of the equipment and pump the materials, and also supply the gas consumed by the entire factory from the facilities:

– Production hall with 2 gasoline boilers and a mixer with a capacity of 50 tons, along with all accessories and a complete bitumen pumping and transfer system and vacuum batom.

– Air production hall with 2 air production compressors with a total capacity of 300 cubic meters of air per hour and a complete pressure stabilization system and air dryer

– A separate unit of a high voltage substation with a capacity of one megawatt and a hall of electrical control panels with three main panels and 1 capacitor bank and 1 stepdown transformer with a capacity of 850 w.

– Material transfer pipes with more than 2500 meters of pipes and different sizes to transfer materials, air, condensate and gas and material transfer pumps with different

capacities